We have been working on the forefront of innovation and technology to provide top-notch hermetic solutions to our loyal customers for over 50 years. Request a quote.

[/vc_column_text][/vc_column][/vc_row]

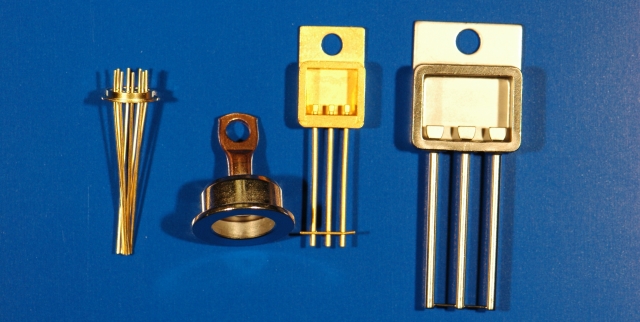

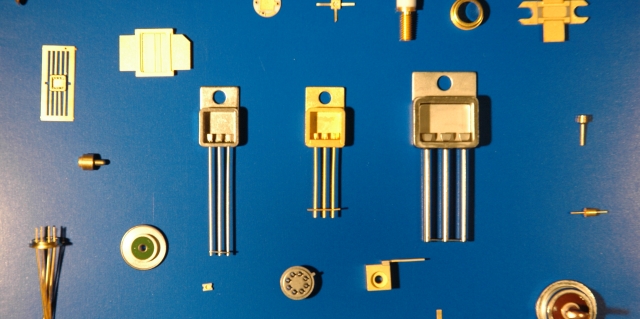

TO-‘s and DO-‘s Hermetic Packages

All TO- and DO- packages (JEDEC) and variations thereof.

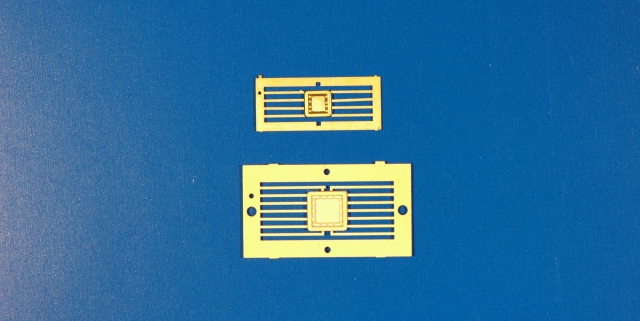

Hybrid Circuit Packages

Flat packs and not so flat hybrid packages too.

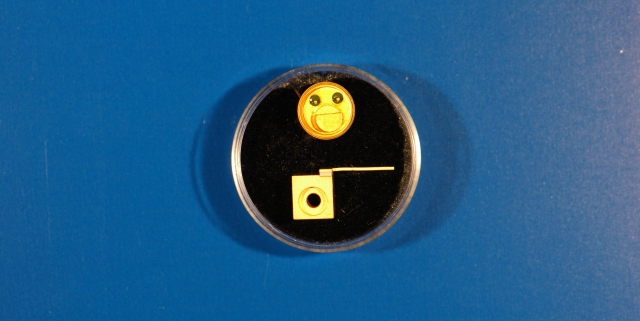

Laser Diode and Optoelectronic Packages

TO packages, C mounts, butterfly packages, etc.

Feedthrus and Hermetic Connectors

Any type of dimension and plating.

Ordnance Applications

Plated, unplated, lapped, ground and not ground.

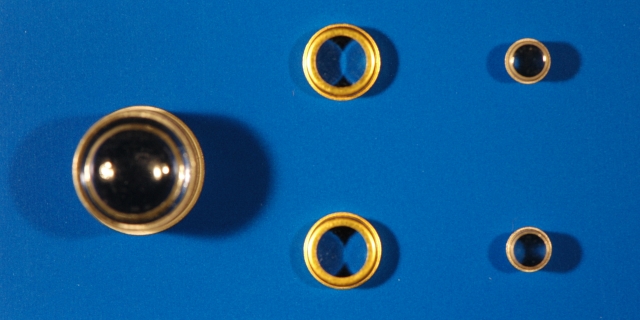

Window Caps/Lenses

Different types of glass and sealing technologies.

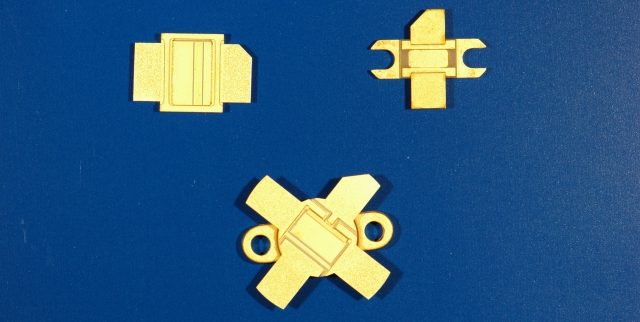

RF Power Transistor Packages

Solutions for the wireless world.

Surface Mount Ceramic Packages and Microwave Device Packages

Solutions with and without leads, many different form factors.

Custom Designs

With our vast experience we can build almost any type of seal.

About

Platronics Seals is a leading provider of high reliability hermetic packages utilizing glass-to-metal seals and ceramic-to-metal seals. For 50 years we have delivered quality solutions at competitive prices across a variety of industries – semiconductor, military, optoelectronic, telecom, aerospace, automotive, and more.

In 2010, Platronics Seals purchased Tech-Ceram, enabling our company to provide ceramic packages. Our sister company, Arizona Plating, works with Platronics Seals to ensure that our products will meet stringent plating requirements that our customers set forth.

We offer solutions to our customers within the United States and internationally from our location in Tempe, Arizona. Give us a call and find out how we can help you with your hermetic packages and plating needs. Contact us.

What has been said

The work produced is of word class quality, they are clearly experts in the hermetic packages industry.

Seb Larsson

Platronics Seals are the experts in hermetic seals and it shows.

Ben Fitzgerald

Platronics Seals demonstrated great flexibility to meet our requirements and fulfill our volumes.

Jack Hewitt

There is incredible peace of mind knowing that you’re receiving top of the line products from Platronics Seals.

Elizabeth Vanhoff

We provide high quality solutions to meet all of our customers’ hermetic packages and plating needs.

Our Team

Sam Baar

President

Victor Alcazar

Sales Director

Contact

We’re always interested in providing custom hermetic packages and plating solutions for new industries. Please don’t hesitate to get in touch with us regarding your needs.

If you want to contact us about any issue please call (480) 219-5644 or send us an e-mail. If you would like to submit a proposal for consideration simply submit a request for a quote.